Knauf Super Lupp Lime-Cement Lightweight Render 20kg

Special, fast-setting lime-cement lightweight render with fibres and lightweight aggregates, Type II lightweight plaster, for all normal, thermal insulating and high thermal insulating masonry types made of bricks, aerated concrete, Liapor etc., as well as precast wall panels and other wall substrates that are to be finished with a top coat.

Pre-treatment is necessary on various substrates.

Properties:

- Lightweight mortar LW / Compressive strength category CS II according to DIN 998-1

- Mortar group P II according to DIN V 18550

- Type II lightweight plaster

- With EPS additive and fibre reinforcement

- Water-repellent

- Diffusion-open

- Weather-resistant

- Low-stress

- Primarily for exterior use

- Suitable for machine or manual application

- Grey

Application purpose:

For all normal, thermal insulating and high thermal insulating masonry types made of bricks, aerated concrete, Liapor etc., as well as precast wall panels and other wall substrates to be finished with a top coat.

Pre-treatment is necessary on various substrates.

- As an interior and exterior base coat

- As a base coat for small-format tiles (? 60 x 30 cm) in domestic bathrooms and kitchens

Application:

Apply Super Lupp in a minimum thickness of 15 mm onto prepared plaster substrate, trowel evenly and finish with a darby. For top coats with Mak3, apply at least 15 mm of Super Lupp fully covering, trowel in a straight line and then roughen with a coarse brush. If necessary, embed a surface near substrate reinforcement mesh 8x8. Depending on the substrate, ridges, unevenness etc. can be removed after approx. 2 hours with the grid trowel. Perform a scratch test with the grid trowel. Super Lupp is a accelerated material; spray interruptions are a maximum of 15 min. (up to 25 min in cooler weather). For longer breaks, clean machine and hoses. Do not leave mortar and water hoses in the sun. Process material that has set.

Preparation:

Normal absorbent substrates can be plastered without pre-treatment. On highly absorbent substrates, apply wet-in-wet. First apply a layer of 5-10 mm and then apply the second layer wet-in-wet up to the required plaster thickness. For non-absorbent substrates, apply a mineral adhesion bridge with SM700 Pro, SM300, Base Coat-SM or Lustro.

Application:

After pre-treating the substrate, allow the primer applied to the substrate to dry completely. Base coats are usually processed with a mixing pump, e.g., PFT G4/G5, which is particularly efficient and time-saving. They can also be applied manually to the wall. Afterwards, distribute the plaster evenly with a trowel or straightedge and finish with a stiffening trowel.

Drying:

The finished base coat must be completely dry before further coating. The drying time depends on the plaster thickness and external conditions such as weather, temperature, etc. To prevent too rapid drying, exterior plasters should be protected from direct sunlight. Generally, the drying time is at least 1 day/mm of plaster thickness.

Safety Data Sheet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Safety Data Sheet.pdf | ||||||||||

| 15.04.2015 | ||||||||||

Occupational Safety and Storage | ||||||||||

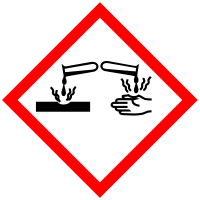

H315 Causes skin irritation. H318 Causes serious eye damage. H335 May cause respiratory irritation. | ||||||||||

P102 Keep out of reach of children. P261 Avoid inhalation of dust/fumes/gas/mist/vapour/aerosol. P280 Wear protective gloves/protective clothing/eye protection/face protection/ hearing protection. P305+P351+P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses if present and easy to do. Continue rinsing. P310 Immediately call a POISON CENTRE/doctor/ P501 Dispose of contents/container in accordance with local regulations. | ||||||||||

13 Non-flammable solids not classified under the above storage classes | ||||||||||

| 1 - Slightly water hazardous | ||||||||||

Hazards | ||||||||||

| Danger | ||||||||||

| ||||||||||

Ingredients | ||||||||||

| ||||||||||