Schlüter-BEKOTEC-THERM underfloor heating

The large-scale heat distribution throughout the entire room makes underfloor heating the ideal medium for ecological and economical heating.

However, in practice, it is difficult to reconcile the structural, physical, and heating requirements for underfloor heating. The specifications set out in the regulations, for example regarding screed thickness, expansion joints, reinforcement inserts, or residual moisture, have often proven to be insufficient in practice. Conventional heating screeds with tile coverings often develop bulges and cracks. This is partly because screed and tiles expand or contract differently when exposed to temperature changes due to their differing thermal expansion coefficients.

In terms of heating, the relatively large screed mass of conventional structures has the disadvantage that a lot of heat energy must first be supplied and stored. As a result, conventional underfloor heating can be slow to respond to temperature changes.

The complete Schlüter-BEKOTEC-THERM system provides a comprehensive solution to these problems and is protected by an international process patent. The name “BEKOTEC” stands for the covering construction technology and “THERM” for the heating components. The system is based on a thin-layer screed that is applied to the BEKOTEC studded panels and reduces compressive stresses in the stud grid.

Schlüter®-BEKOTEC-THERM – The ceramic climate floor

The system structure

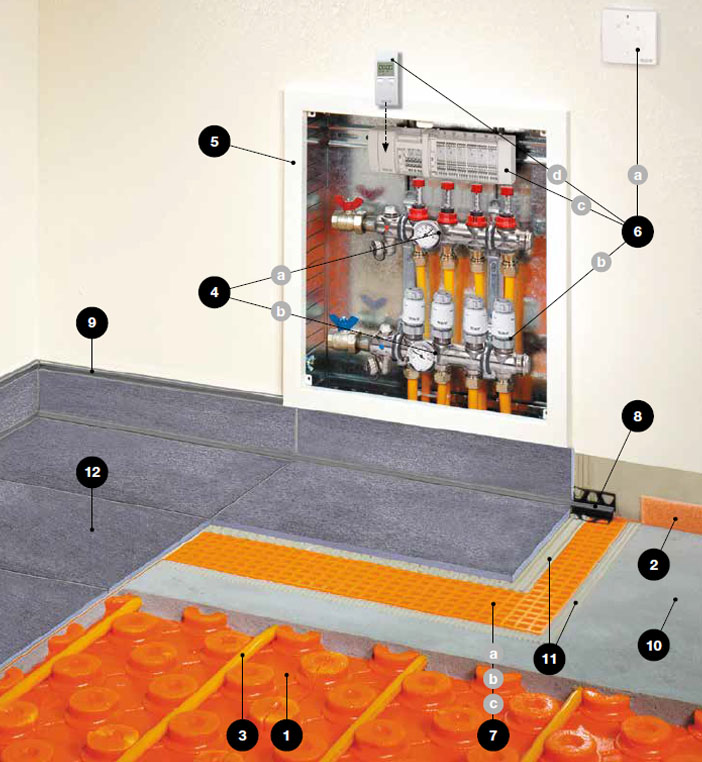

The illustration shows the structure of the Schlüter®-BEKOTEC-THERM ceramic climate floor with the associated system components. The numbers in the illustration can be used to identify the corresponding products in the system structure. Detailed information is also available in the relevant technical documentation.

System components Surface heating

1. Schlüter-BEKOTEC-EN

Screed stud panel for holding Schlüter heating pipes

Note: Additional insulation and building waterproofing must be taken into account in accordance with the applicable regulations.

2. Schlüter-BEKOTEC-BRS

Screed edge strip

The BRS 808 KSF edge strip must be used for the EN 12 FK, EN 23 F, and EN 18 FTS screed studded panels.

3. Schlüter-BEKOTEC-THERM-HR

Heating pipe

4. Schlüter-BEKOTEC-THERM-HV

Stainless steel heating circuit distributor with connection accessories

Flow

Return

5. Schlüter-BEKOTEC-THERM-VS

Distribution cabinet

6. Schlüter-BEKOTEC-THERM-E

Electronic room control

a) Room sensor

b) Actuator

c) “Control” base module with connection module

d) Timer unit (optional)

7. Schlüter-DITRA 25

Composite decoupling, sealing, vapor pressure equalization, heat distribution, or

b) Schlüter-DITRA-DRAIN 4

Composite decoupling, heat distribution, vapor pressure equalization, or

c) Schlüter-DITRA-HEAT-E

Composite decoupling, sealing with electric floor heating

8. Schlüter-DILEX-EK oder -RF

Maintenance-free edge and movement joint profiles

9. Schlüter,-RONDEC, Schlüter-JOLLY oder Schlüter-QUADEC

Decorative wall and skirting boards

System components available in our shop:

10.

11.

12.

Other floor coverings, e.g. carpet, laminate or parquet, etc., are possible in accordance with the respective installation guidelines.

Systems for refurbishment/renovation

Schlüter-BEKOTEC-EN 18 FTS

With integrated impact sound insulation, it is laid as a floating floor, but directly on load-bearing substrates.

Schlüter-BEKOTEC-EN 12 FK

is bonded directly to load-bearing substrates.

Please send inquiries to: info@bauschnell.de