ARDEX B 12 Concrete Filler 25kg

Best before: 05/2025. Goods are excluded from return and warranty.

Application area:

Smoothing, patching, leveling, and coating of wall and ceiling surfaces made of exposed concrete, precast concrete elements, cement or lime-cement plaster, and raw masonry.

Filling cracks, holes, and large depressions on walls and ceilings.

Smoothing interior wall surfaces made of gas concrete.

For outdoor and indoor use.

Type:

Gray powder based on cement.

When mixed with water, it forms a smooth, paste-like, cohesive mortar that is easy to process and, through hydration and drying, cures in any layer thickness to an almost stress-free, breathable mass of cement gray color, which is water- and weather-resistant and adheres practically irreversibly to any suitable substrate.

Substrate preparation:

The substrate can be dry or moist but must be rough, solid, and free of dust, dirt, and other separating agents.

Paint coatings, plaster residues, lime splashes, etc., must be removed. Metals must be protected against corrosion, which also serves as an adhesion bridge.

Processing:

In a clean mixing container, add clear water and mix vigorously while adding enough powder to produce a smooth, paste-like, lump-free mortar.

For mixing 25 kg of ARDEX B12 powder, approximately 8.5 liters of water are required. The mortar is workable at +18°C to 20°C for about 45 minutes and can be applied in one working step, unstriated, several millimeters thick, or stretched to any thickness. It cures through hydration and drying at normal temperature in about 2 hours, making further processing such as sanding or re-smoothing with ARDEX B12 possible.

For layer thicknesses from 5 mm, the ARDEX B12 mortar can be extended with washed sand of grain size 0 to 4 mm up to one-third of the mortar volume; for thicknesses over 10 mm, gravel of grain size 4–8 mm should be used for extension.

To match the color of surrounding concrete surfaces, the cement-gray ARDEX B12 concrete filler can be lightened with ARDEX F11 facade filler (white) or colored with cement-compatible pigments. The ARDEX F11 powder can be mixed into the ARDEX B12 mortar in any quantity. Pigments should first be mixed with water and then incorporated as pastes into the mortar. The color additive can be up to 5% by weight of the ARDEX B12 powder.

Settlement cracks can be closed with ARDEX B12. Fine settlement or plaster cracks should be widened before filling with ARDEX B12 mortar. Movement in the building structure may cause cracks to reappear.

In case of doubt, a trial application is recommended.

ARDEX B12 should be processed outdoors and indoors at temperatures above +5°C.

Post-treatment:

After drying through, ARDEX B12 can be painted over with lime-resistant paint. The drying time depends on the layer thickness and the prevailing weather conditions. A damp substrate may cause efflorescence.

The processing recommendations provided by the paint manufacturers for coatings on cement-bound substrates should be observed, whether full-surface or spot repairs are involved.

Safety Data Sheet | |||||||

|---|---|---|---|---|---|---|---|

| Safety Data Sheet.pdf | |||||||

| 23.06.2016 | |||||||

Work safety and storage | |||||||

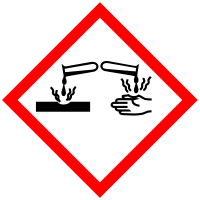

H315 Causes skin irritation. H318 Causes serious eye damage. | |||||||

P102 Keep out of reach of children. P261 Avoid inhalation of dust/fumes/gas/mist/vapors/aerosol. P280 Wear protective gloves/protective clothing/eye protection/face protection. P302+P352 IF ON SKIN: Wash with plenty of soap and water. P305+P351+P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses if present and easy to do. Continue rinsing. | |||||||

| 1 - slightly water hazardous | |||||||

Hazards | |||||||

| Danger | |||||||

| |||||||

Ingredients | |||||||

| |||||||

- Container: Bag

- Item weight: 25,00 kg

- Content: 25,00 kg

- GoogleShopping: Aktion